The Network Cabling Technician Profession: Duties, Routine, and How to Succeed in the Field

The profession of a Network Cabling Technician—often referred to in the US as a Low Voltage Technician, Structured Cabling Tech, or Fiber Optic Splicer—has become essential in today’s world. Malls, airports, manufacturing plants, data centers, and corporate offices depend on reliable network infrastructure. This professional is the one ensuring that the entire Physical Layer (Layer 1) connects and functions correctly.

If you want to understand what a Low Voltage Technician does, what the daily routine looks like, which tools are necessary, and what you need to master to build a career in the US trades, this guide is for you.

What does a Cabling Technician do?

The Technician is responsible for the installation, maintenance, and organization of network infrastructure. Their work involves both copper cabling (Cat5e, Cat6, Cat6A) and fiber optics.

Most Common Activities:

- Cable Pulling: Running cables through conduits (EMT), cable trays, J-hooks, and ladder racks.

- Termination: Terminating jacks (RJ45), patch panels, and 66/110 blocks.

- Fiber Optics: Mechanical and fusion splicing (LC, SC, MPO connectors).

- Cable Management: Dressing cables in racks (using velcro/zip ties) and labeling according to prints.

- Testing & Certification: Using Fluke testers to ensure standard compliance.

- Support: Physical troubleshooting for IT infrastructure.

It is technical, manual work that demands attention to detail and strict adherence to codes (NEC).

What is the routine like?

The routine varies depending on whether you work for a small contractor or a large union shop, but certain elements are universal.

1. Reviewing Prints and Scope of Work (SOW)

Before starting, the technician and the lead/foreman analyze the blueprints (floor plans) to identify cable pathways, drop locations, and closet locations (MDF/IDF).

2. Material Staging

Includes sorting the boxes of cable (pull boxes or spools), organizing j-hooks, faceplates, jacks, and ensuring the correct ladders or lifts are available.

3. Rough-in (Cable Pulling)

A large part of the work consists of:

- Pulling cable through ceilings (plenum spaces) and walls.

- Working on scissor lifts or boom lifts in warehouses.

- Drilling penetrations through firewalls (and properly firestopping them—a critical code requirement in the US).

4. Trim-out (Termination)

The technician organizes the cables in the server rack, punches down patch panels, installs wall plates at the user end, and mounts Wireless Access Points (WAPs).

5. Testing and Certification

Every cable run is tested. In commercial jobs, a “Certification Report” (usually from a Fluke Versiv unit) is required to get paid.

6. Safety Meetings (Toolbox Talks)

In the US, safety is paramount. Daily morning briefings about OSHA regulations and site hazards are standard.

Essential Tools Every Technician Must Master

In the US, technicians are often expected to have their own “hand tools,” while the company provides power tools and testers.

Basic Hand Tools (The “Everyday Carry”):

- Snips/Electrician’s Scissors: For cutting cable and kevlar.

- Punch Down Tool: With 110 and 66 blades.

- Wire Strippers: Specific for UTP/STP cables.

- Crimper: For RJ45 modular plugs.

- Tone and Probe Kit: To trace cables.

- Drywall Saw: For cutting in mud rings/boxes.

- Torpedo Level & Tape Measure: Essential for mounting devices straight.

Advanced Tools (Usually Company Provided):

- Fusion Splicer: For fiber optics.

- OTDR & Power Meter: For fiber troubleshooting.

- Certification Tester: (e.g., Fluke DSX series).

- Hammer Drill / Impact Driver.

Personal Protective Equipment (PPE) – OSHA Mandatory:

- Hard Hat.

- Safety Glasses.

- High-Visibility Vest.

- Steel-toe or Composite-toe Boots.

Infrastructure Knowledge: What You Need to Know

In the US, you don’t just “run cable”; you must follow the NEC (National Electrical Code) and TIA standards.

Indispensable Concepts:

- Plenum vs. Riser: Understanding fire ratings for cables is crucial to avoid code violations.

- Pathway Support: Proper spacing of J-hooks (usually every 4-5 feet) so cables don’t sag.

- Conduit Bending: Basic skills in bending EMT (Electrical Metallic Tubing) are a huge plus.

- MDF & IDF: Main Distribution Frame and Intermediate Distribution Frame organization.

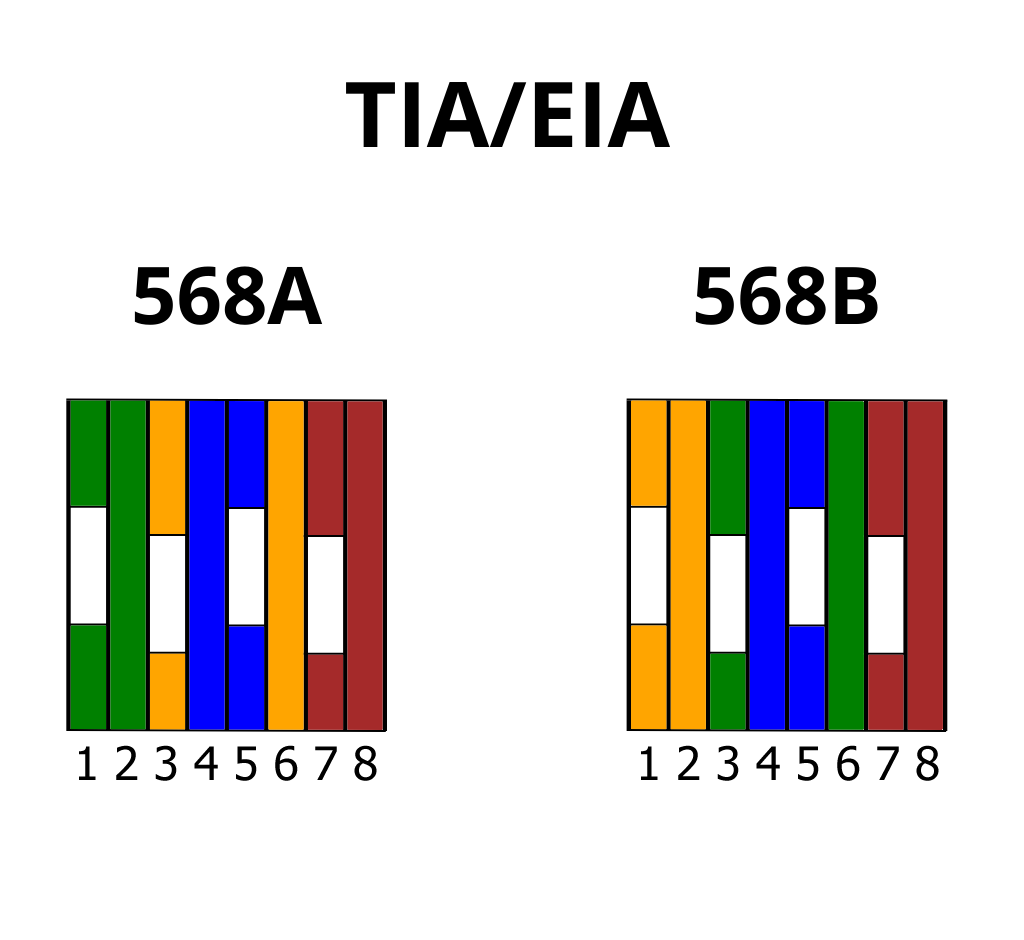

- Structured Cabling Standards: TIA-568 A vs. B color codes (T568B is the most common in the US commercial market).

- Grounding and Bonding: Essential for safety and equipment protection.

Working in Large Environments: specific challenges

1. Commercial & Office Spaces

- Challenge: Aesthetics. Cables must be hidden, and work is often done in “drop ceilings.”

- Note: Often involves working around office workers, requiring professionalism and quiet work.

2. Construction Sites (New Build)

- Challenge: No AC/Heating, dust, and coordination with other trades (electricians, HVAC, plumbers).

- Requirement: Strict PPE usage and “OSHA 10” or “OSHA 30” safety certification cards are often required to step on site.

3. Data Centers

- Challenge: Zero tolerance for error. High-end fiber termination, immaculate cable dressing (combing cables), and strict cooling protocols (hot/cold aisles).

- Status: This is often considered the “elite” environment for a cabling tech.

Salary Expectations (US Market)

Note: In the US, trades are paid by the hour. Rates vary significantly by state, experience, and whether the job is Union (IBEW/CWA) or Non-Union.

Average Hourly Wages:

- Helper / Apprentice (Entry Level): $18.00 – $24.00 per hour.

- Lead Technician (Intermediary): $25.00 – $35.00 per hour.

- Foreman / Fiber Specialist: $35.00 – $55.00+ per hour.

- Overtime: US labor law dictates “time and a half” (1.5x) for any work over 40 hours a week, which is very common in this field.

- Prevailing Wage: Government jobs can pay significantly higher rates (sometimes $60-$80/hr depending on the location).

How to Start in the US

The pathway is different than in Brazil. You don’t necessarily need a college degree, but certifications matter.

- Get Your OSHA Card: An “OSHA 10 Construction” card is the first thing many employers look for.

- Start as a Helper: Apply to “Low Voltage Contractors” or “Structured Cabling” companies. You will learn by carrying ladders and pulling wire.

- Get Certified (BICSI): The BICSI organization is the gold standard. Aim for the BICSI Installer 1 and eventually RCDD (Registered Communications Distribution Designer) for career growth.

- Consider the Union: Look into local IBEW (International Brotherhood of Electrical Workers) chapters for apprenticeship programs.

- Specialize in Fiber: Fiber techs generally earn 20-30% more than copper techs. Learn to use a fusion splicer and an OTDR.

Conclusion

The Low Voltage profession is recession-proof and growing. As long as buildings need internet, Wi-Fi, and security cameras, they will need technicians.

If you are willing to learn the codes, respect safety protocols, and master the art of fiber optics, you can build a lucrative career in the American trades.